Overview of Billet Furnaces Used in Saudi Arabia

Evolution of Billet Heating Systems in the Region

The steel and metal industries in Saudi Arabia have evolved from using traditional reheat methods to utilizing new advancements, such as billet furnaces, in the past decade, due to an increase in demand for production as well as an increase in the need to meet higher standards of quality.

Growing Adaptation of Industrial Furnace Technology

As the number of steel rolling mills, forging units, and other heavy engineering plants continues to grow throughout Saudi Arabia, so too does the use of industrial furnace systems, which include walking-beam, pusher, and induction-style billet furnaces.

The operational role of a billet furnace is to heat semi-finished

steel further hot rolling, forging, or shaping. Using a billet furnace enables you to heat an entire length of semi-finished steel to the same temperature uniformly and supports your metallurgical requirements when producing semi-finished steel products.

Growing Industrial Demand for Efficient Billet Heating

The adoption of billet furnaces within Saudi Arabia’s industrial

sectors are influenced by several factors, such as rapid industrial growth (particularly in areas like construction, infrastructure, and manufacturing), which necessitate the availability of large volumes of quality steel in a short amount of time. The ability of modern billet furnaces to deliver the required volume as well as the desired level of quality helps to ensure that they will become more important to the industry moving forward.

With the increase in production capabilities

Larger steel mills and rolling plants have an associated demand for larger, longer-burning furnaces, capable of producing multiple billet sizes, at higher load weights, and for longer continuous periods of time. These larger mills and plant facilities drive an increased demand for heavy-duty, high-output, long-lasting furnaces.

As a result of the increase in energy costs,

The increasing pressures of the competitive marketplace, the need for an efficient, cost-effective heating solution, which can provide flexibility in fuel sources as well as low levels of downtime, will be critical to the continued success of every steel producer in fulfilling their customers’ needs and maintaining competitive profit margins.

PROPERTY FEATURES OF MODERN BILLET FURNACES IN SAUDI ARABIA

Precision High-Temperature Heating with Uniform Distribution Of Heat Across the Entire Furnace

Modern billet furnaces heat billets evenly/highly controlled in temperature. This will eliminate “hot spots” and “cold spots” in the heating of the billets, thereby ensuring the internal structure of the billet is homogeneous before rolling and/or forging.

Combustion & Control Automation

Most modern furnaces use PLC (programmable logic controllers, or SCADA) for automating the combustion process. The use of PLC/SCADA has improved accuracy and repeatability when controlling the burner flames, the heating zones, the use of the fuel source, and material transfers after heating.

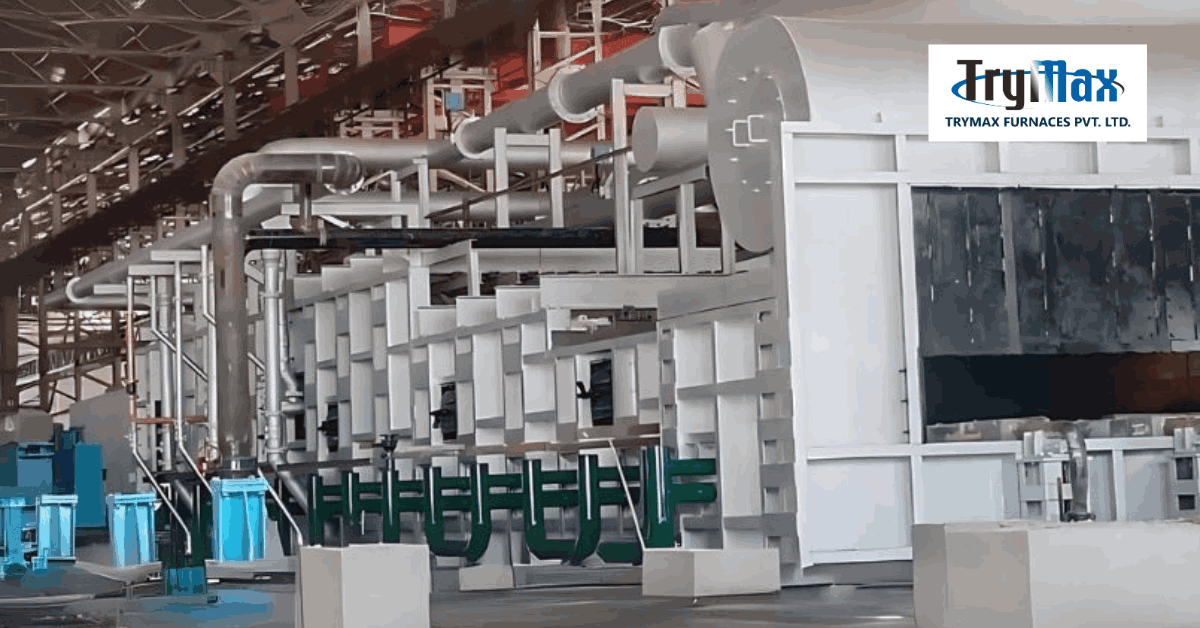

Robust Construction and Durability Permits Continued Operation In Harsh Industrial Environments

Furnace manufacturers have designed these furnaces to be manufactured using heavy-duty and durable items, requiring little replacement/repair due to wear. Furnaces are also designed using very high heat-resistant refractory materials to allow for operating at extreme temperatures for lengthy periods of time without failure.

Energy Efficiency and Performance Improvements

Technology Enabling Low-Fuel-Use Energy Performance Improvements

Because of their advanced designs, such as recuperators, optimized burners, and waste heat recovery systems, these new technologies will drive down operating costs due to all being able to reduce Fuel Consumption

Advanced Designs

Many of today’s newer technologies can be used to recover exhaust heat to help pre-heat the incoming billets or, more typically, for other process needs. By doing this, all systems are able to improve both thermal efficiency and reduce the waste of energy.

Optimized Burners Will Reduce Emissions

By switching to either electric or inductive heating systems or optimising burners to reduce NOx emissions, to an extent, this will greatly benefit the environment, and enable many manufacturers to operate much cleaner than they did in the past with conventional gas or oil burning furnaces.

Applications of Billet Furnaces in Saudi Steel and Metal Industries

Preheating of Billets for Rolling Mill Operations

Before entering rolling mills, billets that first underwent uniform heating will guarantee proper deformation, thus reducing the first-mentioned internal stresses, preventing cracking, and finally, improving the efficiency of rolling as well as the quality of the final product.

Maximizing Output in Metal Shaping Processes

Flame-baked billets are essential materials for the process of forging, extrusion, casting, or any other metal-forming operations; trustworthy furnaces provide a timely supply, consistent quality and temperature, and also very little scrap or defects.

Backing Large-Scale Steel Manufacturing Organizations

In the case of large steel plants producing long products, structural steel, rebars, or heavy sections, the billet furnaces not only provide the needed capacity and flexibility for the different sizes of the billets but also come with durability, which is required for uninterrupted production.

Technological Upgrades Transforming Billet Heating Systems

The Integration of Automation and PLC Controls

Now automation systems take care of everything from temperature control to material handling, burner control, and safety interlocks—making sure that output is repeatable and of high quality and reducing the possibility of human error.

Implementing Smart Monitoring and Data Collection Systems

By monitoring temperatures, fuel-use pressure, and material throughput in real-time, Smart Monitoring Systems give operators the ability to optimize their processes by identifying problems before they escalate into major disruptions and proactively performing preventative maintenance to keep their operations running smoothly.

Implementing Improved Thermally Efficient Furnaces

Advanced refractory materials together with insulation reduce heat losses, leading to furnace temperature maintenance with less fuel, and thus, massive energy savings—this is a big plus for the energy-hungry steel industry.

Benefits of Industrial Furnaces

safety, reliability, and operational efficiency

Modern billet furnaces have been designed to meet industrial safety standards by incorporating flame monitoring, gas leak detection, automated shutdowns, and enclosed heating zones, thus making sure that both personnel and equipment are safe.

Enhanced Reliability Through Modern Automation

The process of automation eliminates the need for manual operation, which means inconsistencies, downtimes, and long reliable performances of the production cycles are reduced.

Reduced need for maintenance thanks to stronger designs.

Utilizing high-quality materials, optimized design, and controlled heating cycles, modern furnaces need maintenance less often, therefore reducing downtime and the costs associated with operations.

Saudi Arabia’s Future Billet Furnace Adoption

Increasing Demand with Industrial Expansion

The demand for steel in Saudi Arabia will keep increasing along with the country’s infrastructure, construction, and industrial manufacturing growth, and thus the heating capacity of billets. As a result, the use of modern furnaces will be driven even more.

Transition to Green and Energy-Efficient Furnace Technologies

Electric induction furnaces or low-emission designs will be preferred over traditional fossil-fuel systems. This is because sustainability and cost-efficiency are becoming critical.

Steel and Metal Processing Units Growth

Modern billet furnace technologies — which are characterized by higher throughput, better control, lower emissions, and long-term operational reliability — are likely to be preferred in new plants and expansions of existing mills.

Conclusion

Billet furnaces are the mainstay of the steel and metal industry in Saudi Arabia, allowing the movement of raw billets or slabs to high-quality rolled or forged ones. The latest furnace technologies, characterized by precision temperature control, efficiency with energy, automation, and strong design, can help steel mills to satisfy the demanding requirements for both throughput and quality while cutting down on costs and pollution. The capacity of industrial demand and the importance of sustainability will lead the advanced billet furnace systems to be the main contributor to the future steel production of the Kingdom.