After steel billets are heated in a reheating furnace to make them soft and malleable, they are still not ready for rolling. So, they are taken to soaking pits where the steel is heated to conserve heat as well as equalize the temperature before being sent to a forging or rolling mill.

In this detailed post, we will look into what soaking pits are, why they are key in the steelmaking process, and how they operate.

Trymax Furnaces is one of the leading soaking pit furnace manufacturers in India. We manufacture completely insulated soaking pit furnaces designed to hold heat so that the steel gets evenly heated and ready for further stages in the steel production.

What Is A Soaking Pit Furnace?

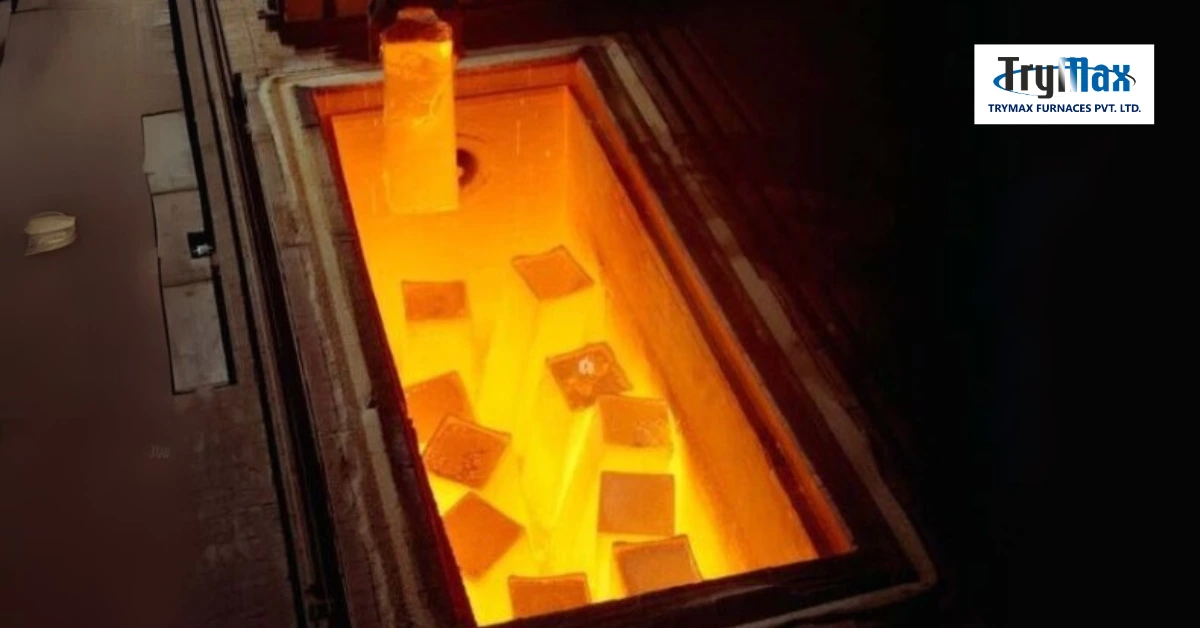

A soaking pit furnace is a pit-type reheating furnace used for the heating or heat preservation of steel ingots before they enter the rolling mills. This furnace is used for holding hot steel ingots to equalise their temperature before they are hot rolled in rolling mills.

The soaking pit furnace is an insulated chamber with a top sliding lid to add or remove ingots. The heat inflow and temperature are controlled inside the chamber.

These furnaces are called soaking pits because the ingots are kept at a high temperature long enough for the heat to soak in through the metal.

What is The Purpose of a Soaking Pit Furnace?

The surface of the steel after casting is hot, but the inside might still be cooler. It is this steel is sent straight to be rolled or forged in the mills, with the temperature difference, the outer layer can deform faster than the core, which leads to cracks, internal stresses, and uneven shaping.

To smoothly pass through different rolling stages in the mill, steel ingots need to be heated and kept at the same temperature all the way through. The soaking pit furnace holds the steel at a constant high temperature—1300°C, which is long enough for heat to sink through the entire block of steel, making its interior and exterior both hot, thus solving the problem.

It is insulated to prevent heat from being lost.

Once the temperature is uniform and the steel is soft, malleable, and safe to work with, it is sent for further processing in forging or rolling mills.

Therefore, the purpose of the soaking pit furnace is to make cast ingots ready for further processing.

How Do Soaking Pit Furnaces Work?

Soaking pit furnaces are critical to the production of steel, since they allow steel ingots to be uniformly heated before processing them into shape in a hot rolling mill.

Soaking pit furnaces are enormous holding chambers that hold the steel at the ideal temperature to avoid quality issues during shaping.

Once heated in reheating furnaces to render the ingots soft and pliable, the ingots are loaded into soaking pits so that heat can be retained, and temperature can be equalized

throughout each steel ingot. Equalized temperature is imperative since every part of the ingot needs to be one temperature before rolling to create high-quality steel.

Design and Structure

A soaking pit furnace is built as a thermally insulated chamber. This insulation prevents heat loss and keeps the temperature stable during soaking. On top, there’s a sliding lid that opens to load or remove ingots while keeping as much heat inside as possible. The walls are lined with special refractory materials that can withstand extreme heat without damage. This ensures the furnace lasts longer and operates efficiently.

Loading The Soaking Pit

The furnace can be loaded in two main ways:

- Directly from the BOS plant (Basic Oxygen Steelmaking plant)—where the ingots arrive already extremely hot.

- From the continuous caster, where hot slabs or blooms are delivered straight into the pit.

Because the ingots are transferred while still hot, the soaking pit has less work to do in reheating them, saving energy.

Temperature And Atmosphere Control

Temperature, airflow, and internal pressure are controlled within the soaking pit. The controlled heating method is essential because, during soaking, both temperature and air flow must be uniform at the soaking temperature and as close to atmospheric pressure as possible. The temperature during soaking is typically controlled at 1,300°C, which is hot enough for the steel to be completely ready for deformation once it enters the rolling mill.

The Soaking Process

Once inside, the ingots stay in the pit for a certain period. During this “soaking” time:

- Heat spreads evenly through the entire ingot.

- Any cold spots are warmed up to match the rest of the ingot.

- The steel remains soft, making it easier to shape later.

This process removes temperature differences within the ingot, preventing defects when the steel is rolled.

Why choose our soaking pit furnaces for your steel production plants?

In steel production and rolling mill operations, a soaking pit furnace is an essential facility that holds hot steel ingots to bring their temperature into equilibrium before the ingots proceed to the rolling mills. Equalized temperature assists with smooth processing through the rolling processes and produces high-quality steel products.

Trymax soaking pit furnaces have been designed and engineered to meet these essential requirements with superior performance, reliability, and flexibility. Here’s why steel plants choose Trymax solutions:

Uniform Temperature Distribution

For consistent and homogenous heating of steel ingots, Trymax soaking pit furnaces are designed to provide all precise temperature control, removing hot and cold spots throughout the ingots and thereby preventing defects such as cracks or inconsistent deformation during hot rolling. Consistent temperatures allow the steel to have the best malleability required for high-quality rolling.

Excellent Fuel Efficiency

Energy costs are a major concern in steel production. The soaking pits offered by Trymax are designed with state-of-the-art combustion systems to maximize fuel efficiency. We engineered our furnace to be very efficient by looking at the entire system. Additionally, our advanced insulation and burner technology reduce heat loss, allowing our furnace to operate with less fuel while maintaining a stable high temperature of approximately 1,300°C. Greater fuel efficiency results in operational cost savings as well as environmental benefits through sustainable manufacturing practices.

Robust Construction for Durability

Trymax soaking pits are fabricated from high-quality refractory materials and designed with a durable subframe that can endure the high-temperature and demanding operating conditions present in steel plants. The heavy-duty construction of our furnaces ensures longer service life with less frequent maintenance, which reduces plant downtime and lifecycle costs.

Reduced Heat Loss

Every effort is made to limit the potential for heat loss from the furnace chamber. Trymax soaking pits provide advanced insulation capabilities and a well-defined environment with a set of sliding lids operating under direct control to reduce any heat losses internally. With reduced heat loss, the temperature levels can remain stable longer, which keeps the ingots hot longer, saves energy, and reduces the need to reheat.

Customization & Flexibility

Every steel plant has unique requirements and therefore Trymax furnaces offer flexible soaking pit designs that can be fully customized.

We provide engineered heating solutions, including dedicated pit sizes, fuel options (gas, oil or dual-fuel), and integration with your existing systems. Trymax custom heater solutions fit perfectly into your operational needs.

We offer various fuel options for our engineered heating solutions to determine the best fuel type based on your availability and price, increasing your overall process flexibility.

Trymax soaking pit furnaces are built to produce quality steel, quickly and efficiently, with minimal requirements for process and adjustment. They offer precision heating and energy efficiency that helps produce consistent products. By investing in the right soaking technology, you will be able to roll with fewer defects, better rolling speeds, and increases in productivity.