Furnace Manufacturing in Saudi Arabia: Trends, Technology, and Industry Growth

Latest Developments And Industry Growth Trends Of Furnace Manufacturers In Saudi Arabia

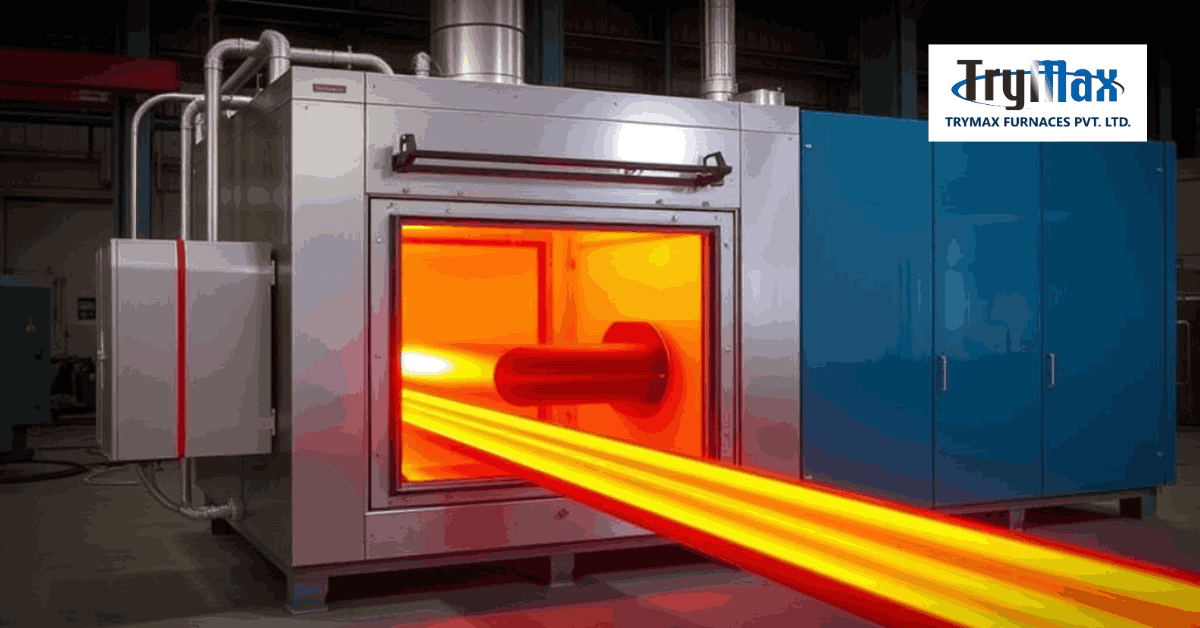

The manufacturing of furnaces has been growing strongly within Saudi Arabia. As a result of increasing demand from the steel, construction, oil/gas, and heavy engineering industries, furnace manufacturers are quickly developing new product offerings and capabilities to meet the demands of these industries by providing substantial heat treatment and thermal processing solutions. There is an ongoing trend in the market toward producing higher-quality, bespoke products that provide consistent and dependable performance in various industrial applications.

Importance of Key Industries in Creating Demand for High-Efficiency Industrial Furnaces

Key industries that drive the demand for industrial furnaces globally include steel manufacturing/processors; petrochemical production (petrochemical); fabrication (foundries) and heavy machinery production; heavy machinery construction and metal working; and oilfield development and environmental protection. Each of these industries uses a variety of heat processes, including: annealing; carburising; quenching; tempering; and solution treating. This allows manufacturers to meet specific mechanical and structural requirements for their high-performance applications by producing parts that are manufactured with high-quality properties and characteristics.

Technological Developments in the Current Equipped Furnace Systems

Innovative technologies are being introduced to the furnace industry due to increased production requirements. Advanced control solutions have integrated:

- Automated controls (i.e., PLC & SCADA-based Interfaces): HMI Control Panels, and Remote Access (Internet Connection) functionality to guarantee precise temperature control, repeatability, and simple operation. (As seen in the offerings of leading furnace manufacturers abroad.)

- Robust build quality and heavy-duty design — capable of handling large load capacities and delivering consistent performance for bulk industrial operations.

- General process capabilities include furnaces that perform a variety of thermal treatments, including annealing, normalising, carburising, solution treating, tempering, stress relieving, and quenching.

- Customisation to client specifications includes the ability of manufacturers to provide custom-built furnaces based on the type of material, size of component, batch capacities, and specific processing requirements.

These developments enable companies to provide high levels of quality, which is internationally accepted and improves not only throughput and energy efficiency, but also ensures that treatments are uniform for all parts processed.

Types of Industrial Furnaces Used in Saudi Arabia

Furnace types commonly utilized — or offered by manufacturers serving the region — include:

- Batch Furnace – For a variety of heat-treatment processes and different-sized load capacities. Flexible processing ability.

- Bogie-Hearth Furnaces – Commonly employed for longer castings and forgings.

- Solutionizing and Carburizing Equipment – For alloy surface hardening and solutionizing treatments needed when specific metallurgical properties or high surface wear resistance are required.

- Quenching / Drop-Bottom Furnaces – Designed specifically for rapid quench operations in high-strength and heavy-duty applications.

- Tempering and Hardening Equipment – Used in post-heat treatments to adjust a component’s hardness or toughness levels as required.

This diverse array gives manufacturers the flexibility to support all types of industrial requirements, including basic components, as well as large industrial and/or fabricated parts.

Compliance, Safety Guidelines, & Environmental Considerations

Manufacturers who manufacture for either the international or the UAE/Middle East markets must develop their furnace designs based on adherence to various strict conformity and quality control specifications. Among the most important things to consider are:

- Global Heat Treating Standards – This includes the construction of Heat Treating Systems according to the specifications for uniform heating (Temperature control) and Processing Control (Process Control) to produce uniform, consistent, and through-process treated products.

- The construction of Energy Efficient and Thermally Insulated Heating Systems – Heat Treat systems will have Excellent Insulation Construction, an effective Heating System, and Ideal System Design, all reduce energy consumption and reduce the overall impact on the Environment, while maintaining a Balanced Thermal Cycle.

- Heavy construction and Operational Safety are required for all heat-treat systems to provide Durability, Safety, & Stability when used in Extreme Industrial Environments that utilize Heavy Loads and frequently undergo Thermal Cycle Processing.

Industrial clients such as Oil & Gas, Petrochemical, Steel Plants, and Large Manufacturing Facilities require Absolute Trust in the Integrity of Components and Reliability in Processing.

Opportunities and Challenges in the Saudi furnace manufacturing industry:

There are currently many potential and difficult situations associated with the manufacturing, selling, and operating of furnaces in Saudi Arabia:

- A Chance to Provide Custom Furnaces: Industries are discovering they can be much more effective in meeting their various needs by using custom furnaces designed to fit their requirements precisely, including the type of heat treatment, batch size, and process cycles. Producers of specialized furnaces have a unique advantage in supplying these customers.

- As industrial processes continue to expand in such areas as infrastructure, petrochemicals, and construction, there has been a substantial increase in the need for high-performance heat treat furnaces.

- To achieve compliance with international standards and demonstrate their superior performance, facilities must have a highly skilled, trained engineering workforce and utilize rigorous quality control methods along with high-quality raw materials.

- Due to the global marketplace becoming increasingly competitive, manufacturers must compete with one another by offering enhancements to their product lines, while maintaining an even balance between cost, quality, customization, and continued maintenance support.

- As the number of environmental regulations continues to rise, it is felt that reduced consumption of fuel, increased regulation of emissions, and maintaining a higher degree of safety will all become increasingly important to manufacturers of heat treat equipment.

Furnace manufacturers and users who navigate these dynamics carefully stand to benefit from long-term industry growth and stability.

The Future of Furnace Manufacturing in Saudi Arabia:

The future of the furnace manufacturing industry will continue to expand due to the diversification of Saudi Arabia’s economy, continued growth of industrial infrastructures, and increasing needs for furnaces in multiple sectors such as steel making, petrochemical production, heavy-duty fabrication, etc. In addition to continued growth in these industries, it also means:

- Increasingly common will be the implementation of automated and digital control systems in the operation of furnace technology that provide improved precision, consistency, and the ability to operate remotely.

- Developed furnace technologies are suited to the unique requirements of each type of material, process, and heat treatment cycle — including but not limited to complex metals and alloys, and high-strength steel materials..

- Furnaces designed and built specifically to meet a manufacturer’s specifications of steel fabrication processes’ energy efficiencies and environmentally conforming practices align with global sustainability trends through compliance with both national and international regulations.

- Provide a comprehensive range of after-sales service, maintenance support, and on-site commissioning for customers — ensuring long-term operational reliability.

In addition to these advancements, increasing the size of the furnace manufacturer’s market and improving efficiency, will contribute to the overall growth and development of the country’s industrialisation programs.

Conclusion

The furnace manufacturing sector in Saudi Arabia currently experiences extreme growth driven by the emergence of heating and cooling industries, technological advancements, and the overall expansion of many industrial sectors. By utilising innovative thermal engineering methods and developing products to meet international standards, as well as offering custom-designed furnaces to cater to specific customer requirements, manufacturers will have the ability to serve a wide range of industries, providing them with the dependability and reliability they need. Therefore, manufacturers and industrial customers alike will benefit from making a substantial investment in the design and development of furnaces, as this enables them to produce stronger, high-performance metal parts, and enhances operational productivity, as well as improves long-term operational sustainability. Thus, the overall outlook for the manufacturing of furnaces in Saudi Arabia is very strong, encouraging, and aligned with world engineering and manufacturing standards.