At Trymax Furnaces, we offer AOD preheaters customizable according to client needs. Our AOD preheating systems are highly efficient in alloy production and refinement.

In the manufacturing process for stainless steel, the AOD process is conducted to remove unwanted components from the molten iron, like carbon, but retain necessary items like chromium, which make the steel shiny and rust-proof.

This process is conducted in a special container called an AOD furnace, which holds the molten iron. It is important to heat the AOD container. For this purpose, an AOD preheater is used.

Here’s a comprehensive guide to understanding the AOD process and the applications of the AOD preheater in the entire process.

What is AOD process in steelmaking?

AOD stands for Argon Oxygen Decarburization. The argon oxygen decarburization process is conducted to remove unwanted components from the molten iron and retain the good components. The unwanted component includes carbon, and the necessary retainable component includes chromium.

Carbon, although necessary in lesser amounts, needs to be removed from the molten iron, as it makes the steel brittle and increases the chances of steel rusting. As a result, there is a reduction in carbon content through the AOD process, leaving chromium intact, which is responsible for corrosion resistance, shine, strength.

How does the argon oxygen decarburization process work?

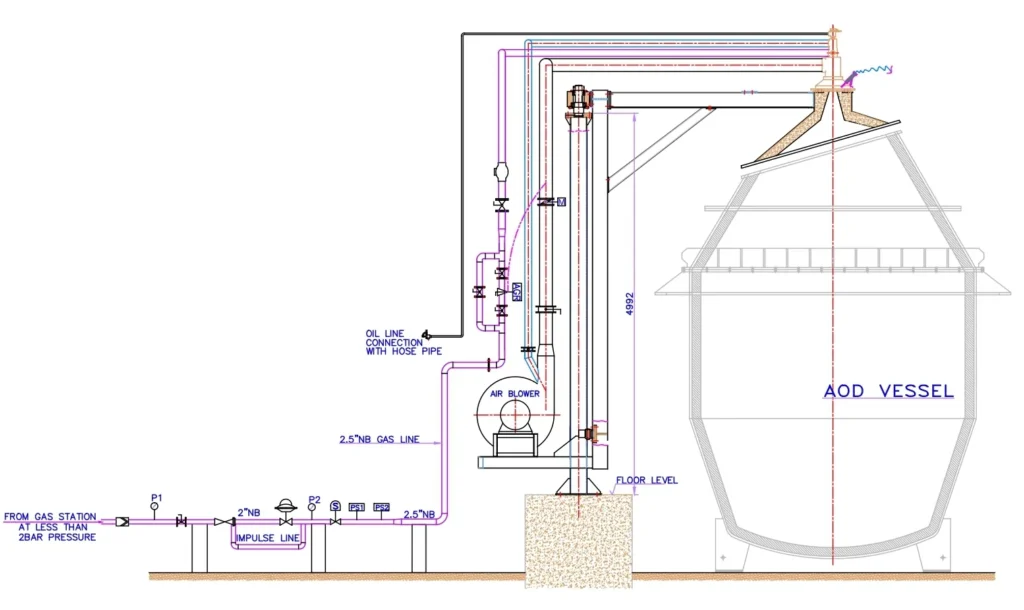

The entire aod process is conducted in an argon oxygen decarburization furnace. This vessel is preheated using an AOD preheater to ensure the process is conducted efficiently.

The molten iron is poured into the AOD furnace. Oxygen is introduced into the molten metal by way of the pipe, which reacts with the carbon in the iron. The carbon reacts with oxygen to form carbon monoxide, which then leaves as a gas. This is the process known as decarburization.

Argon and sometimes nitrogen are added at the same time to retain chromium, as chromium can also react with oxygen and oxidize. Blowing argon lowers the oxygen pressure and chromium is retained to give stainless steel its shine and corrosion resistance.

After removing carbon and retaining chromium, alloying metals like nickel, molybdenum may be added to improve steel quality. The steel is then finally checked for composition and temperature, after which it is poured into moulds or sent to the next stage for shaping into stainless steel products.

What is the purpose of an AOD preheater?

An AOD preheater is used to heat the furnace before the molten metal is poured into the vessel. Preheating the AOD preheater is needed for the following reasons:

- Protecting the refractory lining

The inside of the AOD is designed with heat resistant refractory bricks. In the case the molten hot iron is poured into a cold furnace, the brick quite frankly can crack and break.

- Preventing explosions or splashes

Refractory bricks absorb moisture from the environment. If this moisture is not properly dried, it can form steam, which can cause explosions or splashing of metal at the moment of the pour.

- Keeping the molten steel hot

If you pour molten iron into a cold furnace, the furnace will absorb all heat out of the molten iron, reducing the temperature of the molten iron and somewhat negatively affecting the decarburization of the metal.

How does the AOD preheater work?

The AOD preheater system comprises a burner that is placed near or inside the aod furnace, aiming at the bottom and walls of the vessel. The burner slowly heats the vessel for a few hours, gradually increasing the temperature to around 800–1000°C or more. The temperature is increased slowly step by step to prevent cracks from occurring on the lining of the furnace.

The furnace is dried out as the remaining moisture from the refractory bricks escapes as steam. Once completely dried out, the temperature of the furnace is checked using temperature sensors, and the dryness is checked using infrared guns.

Once the target temperature is reached and the furnace is dry, the furnace is ready for pouring molten steel, after which the argon oxygen decarburization takes place.

What makes our AOD preheaters the best choice for your steel plants?

Our AOD preheaters at Trymax are suitable for a wide range of metal grades and can be used on many types of stainless steel and specialty alloys. These preheaters are designed to optimize the temperature of AOD vessels before they enter the refining process, ensuring energy efficiency and extending refractory life.

With PID/PLC-based temperature control systems, our preheaters deliver precision heating cycles to lower fuel consumption rates and improve metallurgical grade quality.

Our aod heating systems are easy to use, operate, and adapt to fit a factory or process, regardless of differing production requirements to match the factory or production process.

Reinforcing our commitment to high performance and efficiency, our aod preheaters are used for producing high-quality refined stainless steel (free of unwanted elements, such as carbon) and have improved properties such as corrosion resistance, strength, etc. through the minimization of slag.

Choose Trymax AOD preheaters to ensure efficient and reliable stainless steel refining and delivery of superior stainless steel every time.