A ladle is like a giant bucket made of strong, heat-resistant material. It must be heated before the molten metal is poured; that’s where ladle preheaters come in.

In the steel industry, ladles are used to transport hot, molten metals, usually iron, from the furnace to other parts of the steelwork, including casting machines. In the casting machine, the steel is cast into billets, blooms, or slabs, and then heated once again in a reheating furnace to become soft and malleable.

What is a Ladle Preheater?

Before pouring molten metal into a ladle it is important to preheat the ladle. Pouring liquid metal, especially metal of very high temperature, into a cold ladle, can crack or damage the lining of the ladle, which would create heat loss using the terms of the quality of the metal. Using a cold ladle may also put operators at risk if the cold ladle suddenly reacts with the hot liquid metal to create a splash. Ladle preheating involves heating the ladle to a temperature where it can hold the molten metal safely and efficiently.

A ladle preheater is a machine that heats the ladle before pouring hot liquid iron into it. The ladle is heated at a very high temperature so that the ladle is hot enough to handle the molten metal.

Trymax Furnaces Pvt Ltd., a leading ladle furnace manufacturer, produces the most energy-efficient and durable ladle preheater system tailored to your specific needs.

How Does A Ladle Preheater Work?

In steel mills, ladle preheating is intended to heat the refractory lining in the ladle to the high temperatures that are required before the ladle receives molten steel, generally above 800°C and sometimes to 1000°C. Adapting the previous context to reflect these requirements and the new operating characteristics:

Positioning and Starting The Burner

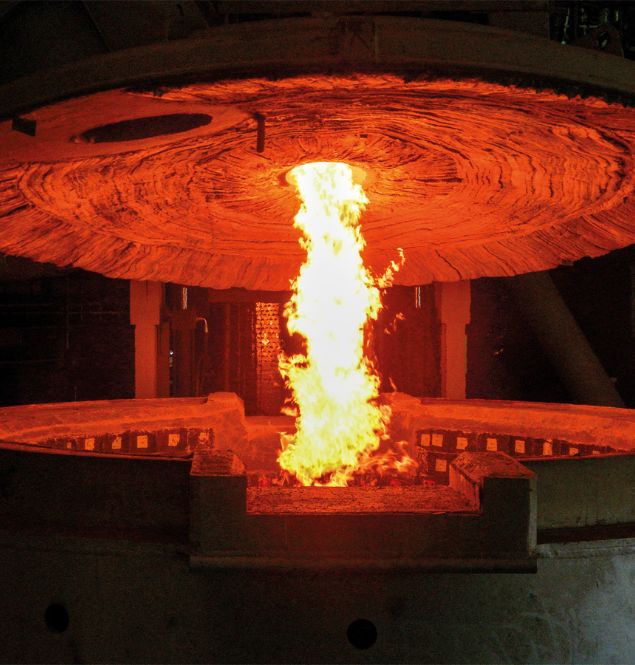

The ladle is placed under the preheater unit, with the ladle positioned accurately under the heating hood or cover. The ladle heating burner a high-capacity gas burner is then engaged. This burner holds a steady flame over and possibly into the ladle that can be used to heat the refractory inner lining of the ladle rapidly and uniformly.

High-Temperature Refractory Heating

The main objective for the ladle heating operation is to heat the ladle lining to temperatures between 800°C and 1000°C. The high temperature will match the temperature of the molten steel and allow time to transfer the metal in the ladle without substantial heat loss or thermal shock of the ladle lining. The burner assembly may also use ancillary devices, like recuperators for heating combustion air, which improve temperature use efficiency of the burner.

Optional Rotation For Uniform Heating

On some systems, a ladle-sized heater may also be rotated during the heating operation. The rotation of the ladle will ensure that all parts of the inner lining material will be uniformly exposed to the heat source, ensuring that cold spots are avoided, and the internal lining material will have a uniform temperature distribution throughout.

Thermal Monitoring and Control

Sensors (e.g., thermocouples or pyrometers) continuously monitor the temperature of the refractory lining, while the control system modulates burner power to follow the prescribed heat-up curves. Heating usually occurs in stages to prevent damage to the refractory and extend its life.

Readiness for Mould Steel Handling after Heating

Once the ladle refractory lining has reached its final temperature, the ladle can be safely filled with molten steel for transport to casting or to another processing area within the plant. Proper preheating will reduce thermal shock, optimise steel temperature during transport, and improve efficiency and quality in downstream processing.

Some modern preheater systems include a movable hood design with advanced seals to reduce heat loss and improve heating efficiency.

Built-in safety features (flame safeguard and fuel-air ratio control) are required to safeguard against overheating, damage to the refractory lining, and ignition of fuel gases.

The preheating of the ladle at a steel plant is an engineered system: The ladle is positioned below the burner, evenly heated (with some systems including ladle rotation), controlled up to 800–1000°C, to reach safe conditions for handling molten steel in a safe and efficient manner for transport and processing.

What are the types of ladle preheaters?

There are two main types of ladle preheaters based on their design:

Vertical Ladle Preheater

Vertical ladle preheaters are used for drying and heating ladles. In this type of preheater, the ladle is placed in an upright position, and the burner is placed on top, pointing downwards into the ladle. The ladle is heated evenly from the top. As this preheater is vertical, it takes up less space on the shop floor.

Components of a Vertical Ladle Preheater

Vertical Structure & Lift Mechanism

Tall vertical frame with guide rails.

Hydraulic, electric, or manual lifting mechanism allows vertical travel of the burner and cover assembly for easy loading/unloading of the ladle.

Burner System

Down-fired burners mounted in the center of a refractory-lined hood, firing directly downward onto the ladle’s internal surfaces.

Compatible with multiple fuels: natural gas, LPG, furnace oil, or dual fuel per client needs.

Refractory Insulated Hood/Cover

Robust cover lined with ceramic fiber or castable refractory for high heat retention and energy efficiency.

Designed to seal the ladle mouth and contain heat for rapid and uniform heating.

Frame, Bearings, & Swivel Mechanism

A cantilever arrangement or vertical frame provides support and enables safe, stable positioning.

Swivel or pivot mechanisms allow the hood to be rotated or moved as required.

Combustion Air Blower & Accessories

High-volume blower system supplies air required for efficient combustion.

Airflow meters and control valves ensure precise delivery.

Instrumentation & Automation

Optional advanced PLC-based control for heating cycles.

Safety & Energy-Saving Features

Overheat protection, automated purging, and emergency shutdown systems.

Recuperators or energy-saving attachments available for improved efficiency.

Horizontal Ladle Preheater

Horizontal ladle preheaters are the type of ladle preheaters in which the ladle lies on its side in a horizontal position. The ladle preheater burners are placed in front of the open side and blow heat directly into the ladle. These preheaters are usually used for heating smaller ladles or those mounted on moving carts.

Components of a Horizontal Ladle Preheater

Steel Structure & Frame

Heavy-duty horizontal steel frame for durability and stability.

Fabricated stand designed to support and position the ladle securely during heating.

Trolley mounting for ease of movement within the facility.

Burner System

Advanced combustion burners (natural gas, diesel, LPG, or dual fuel) positioned to fire horizontally into the ladle.

High-efficiency, rapid heating burners with options for energy-saving recuperator technology.

Burner accessories include atomization units and control valves for precise fuel and air delivery.

Blower & Combustion Air System

High-power centrifugal air blower to deliver combustion air to the burner.

Flexible hose and pipeline arrangement accommodating trolley movement.

Integrated air flow control for optimal combustion.

Refractory Lining

Internal surfaces protected by high-grade refractory castable or ceramic fiber blanket.

Ensures heat retention, protection of ladle shell, and minimizes energy loss.

Cover System

Insulated cowl/cover designed to seal the ladle opening and direct the heat efficiently.

Vertical heat shield enhances uniform heat distribution.

Fuel Oil Supply & Control

Pumping, filtering, and pressure control unit for fuel supply where oil is used.

Safety valves and motorized control valves for secure operations.

Instrumentation & Automation

Optional PLC/PID/PPID control for automated heating cycles.

Temperature sensors provide feedback for precise control.

Auto ignition and auto shut-off for operational safety.

Other ladle preheater types include twin ladle preheaters, rotary ladle preheaters, swing-type ladle preheaters, tilting ladle preheaters, car-mounted ladle preheaters, etc.

At Trymax Furnaces, we offer both vertical and horizontal preheaters customizable as per client requirements, running on both oil and gas.

Trymax Furnaces’ horizontal and vertical ladle preheaters combine advanced engineering, high-grade manufacturing, and flexible automation for optimized ladle heating in steelmaking and foundry operations.

Why choose our ladle preheaters?

At Trymax Furnaces, we offer customizable ladle preheating systems, which have earned a name for themselves for their flexible ladle heating.

Our preheaters are available in both horizontal and vertical designs, expertly tailored for a perfect fit with your unique ladle sizes and operational needs.

Our ladle preheating systems reduce production costs due to their low maintenance and fuel efficiency.

Our ladle preheaters use premium mild steel and steel to provide strength, excellent heat retention, durability, and a long life in rigorous foundry conditions.

We also make things comparatively easier for your process with easy installation and tidy operation, so that your team can get set up fast and get moving for faster heating rates.

Trust in our reputation—Trymax Ladle Preheaters have established themselves as a go-to choice in the industry for their uncompromising reliability and consistent results.