Get In Touch

- 55 Main Street, 2nd Block, USA

- [email protected]

- +000 (123) 456 88

Gallery

Get In Touch

- 55 Main Street, 2nd Block, USA

- [email protected]

- +000 (123) 456 88

Gallery

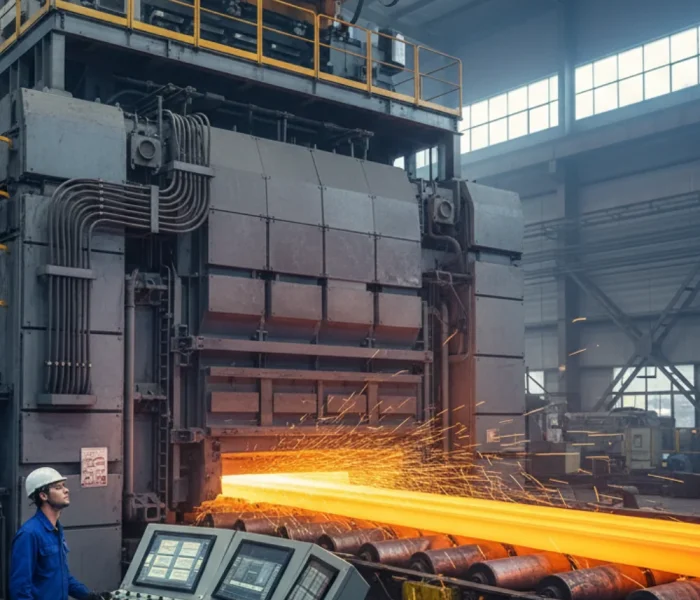

Billet Reheating Furnaces: Powering Steel Production Efficiency for Iraq

High-performance billet reheating furnaces engineered to support Iraq’s expansion of domestic steel production capacity. They deliver exceptional billet quality, superior energy efficiency, and optimised operational performance. Each furnace is custom-designed to align with Iraq’s integrated steelmaking supply chain and cost-competitive manufacturing objectives. Advanced automation, precise temperature control, and robust construction are seamlessly integrated to ensure maximum reliability in demanding industrial environments.. With capacity options ranging from 1 to 120 TPH, our furnaces support a comprehensive range of steel billet, bloom, and slab sizes. They are compatible with multiple fuel sources, including natural gas, furnace oil, and LPG. This versatility positions your facility to capitalise on Iraq’s abundant energy resources and competitive regional market advantages.

About Trymax Furnaces

Trymax Furnaces was established in 2012 to serve as a leading name in industrial furnace manufacturing, delivering advanced heating technologies for steel producers and the metal-processing industries worldwide. Based in Mumbai, India, the company has built a strong global footprint, supplying high-performance furnace systems to over 20 countries, including Iraq and other markets across Asia, Europe, and beyond.

The product range of our company includes everything, starting from billet reheating furnaces and treatment furnaces to ladle and tundish preheaters, AOD preheaters, and recuperators for hot steel rolling mills. With Trymax Furnaces, you are assured of more than 12 years of trusted expertise, international credibility, and long-term partnership in improving your operational efficiency to the fullest.

What is a Billet Reheating Furnace?

A billet reheating furnace is a type of industrial furnace that heats semi-finished steel products-cold billets, blooms, and slabs-along with other metal parts to a uniform, optimal temperature for further hot rolling, forging, and other metal forming operations. These furnaces bridge the casting process to hot rolling and are therefore very crucial in the transformation of the raw metal into finished products during the manufacture of steel.

Trymax Furnaces provides billet reheating furnace solutions, specially designed for steel rolling mills, forging shops, and metal processing industries. With a complete range of billet reheating furnaces, we are capable of providing various production capacities and operational requirements. Types of these furnaces include pusher type, walking beam, and top and bottom fired billet reheating furnaces. Our reheating furnaces for billet are designed for high efficiency, exact temperature control, and reliable operation in the most demanding environments.

Key Features of Trymax’s Billet Reheating Furnace

- Continuous Heating Design: Provides for continuous processing with accurate temperature control and uniform heat distribution throughout all the billets to minimize down time while maximizing production flow.

- High Energy Efficiency: Advanced recuperators and precision-engineered burners can lower fuel consumption, offering cost savings while also supporting sustainable industrial operations in Iraq.

- Precise Temperature Control:PLC-based automation systems and IoT-ready sensors maintain uniform temperatures between 200–1250°C, ensuring consistent billet quality and its metallurgical properties.

- Flexible Capacity Range: Capacity options available from 1 to 120TPH, catering to the small and large-scale steel mills, forging, and rolling for the Iraqi metal processing sector.

- Multi-Fuel Compatibility: It is compatible with furnace oil, natural gas, LPG, and various dual-fuel combinations, thus enabling Iraqi operators to choose the most economically viable and accessible fuel.

- Reduced Scale Formation : Optimised burner design and controlled heating minimise oxide scale on the billet surfaces to reduce downstream processing time and material waste, improving the final product yield.

Established

Completed

Served

Energy

Inefficiency

Significant energy inefficiencies are driving excessive fuel consumption to maintain production temperatures. Without heat-recovery systems, 10–50% of valuable thermal energy is lost through exhaust gases.

Uneven Temperature Control

Poor control of gas pressure and burner performance makes it difficult to maintain uniform billet temperatures across the heating chamber. This results in inconsistent heating leading to significant material waste.

Limited Production Flexibility

New facilities like the Basra mill demand furnaces that can rapidly scale production to meet fluctuating needs for industrial steel products. Inability to adapt forces manufacturers to operate below capacity or reject orders for non-standard billet sizes.

Maintenance

Complexity

Frequent manual maintenance and adjustments are required to maintain operational stability. Rapid deterioration of subcomponents under constant thermal stress causes unexpected shutdowns and downtimes.

Challenges faced by Steel Manufacturers in Iraq

How Trymax's Advanced Billet Reheating Furnaces Solve These Critical Challenges?

Advanced Recuperators for Energy Efficiency

High performance industrial recuperators in our furnaces capture waste heat from exhaust gases and redirect it to preheat incoming combustion air significantly increasing furnace efficiency.

PLC Based Precision Temperature Control Systems

Advanced PLC automation with IoT-ready sensors ensures uniform furnace temperature through continuous monitoring and adjustment. It suppresses gas-pressure fluctuations and maintains stable heating curves.

Flexible Multi-Furnace Architecture

Multiple furnace configurations are available to match different production profiles. This flexibility enables facilities like the Basra mill to choose a setup that aligns precisely with their production rhythm and billet dimensions.

Real Time Diagnostics and Predictive Maintenance

Advanced diagnostics with real time monitoring and automated maintenance alerts identifies potential issues before they cause shutdowns, minimising production interruptions and protecting supply reliability.

Technical Specifications of our Billet Reheating Furnace

Furnace Types:

Walking Beam, Hearth, Slab Reheating

Capacity Range:

20–250 TPH, scalable designs

Operating Temperature:

1,350°C max, uniform heating

Fuel Options:

Natural Gas, FO, Producer Gas, Mixed Fuels

Beam Mechanism:

Low-friction beam movement, optimized billet transfer

Heating System

High-efficiency low-NOx burners

Control System:

PLC/SCADA with temperature precision

Material Handling:

Billets, blooms, slabs

Types of Billet Reheating Furnaces for Iran Market

This type of furnace features mechanical pushers that continuously advance billets through preheating, heating and soaking zones. These are engineered to minimise billet deformation and support continuous operation, reducing downtime.

With specialised lifting beams, walking beam furnaces gently transport billets forward step by step through several heating zones. This leads to uniform heating without surface marking ensuring consistent metallurgical billet quality.

In this furnace, the burners are positioned strategically above and below the billets for uniform heating. Dual firing approach accelerates heating cycles, reduces fuel consumption and minimises oxidation losses.

Our Billet Reheating Furnace Process Workflow

01

Loading Billets

The steel billets are situated at the furnace entrance, positioned accurately for the heating cycle.

02

Preheating Zone

As the billet moves forward, the exhaust heat raises their temperature gradually and therefore paves the route for higher temperatures with minimum thermal shock and greater energy efficiency.

03

Heating Zone

In this zone, strong burners or induction systems increase the temperature of the billet up to rolling or forging levels, generally above 1,100°C

04

Soaking Zone

The area where the billets rest to let the heat reach the core uniformly is for consistent internal integrity and quality.

05

Temperature Monitoring

Advanced sensors and automatic controls maintain the set temperatures during the process without overheating or hot spots.

06

Cooling Billets

When the temperature required in the billets is attained, they leave the furnace and head straight for rolling, forging, or further shaping at red heat.

Billet Reheating Furnaces in Iraq

Trymax furnaces operate on natural gas, furnace oil, and LPG with single-fuel, dual-fuel, and triple-fuel burner configurations. Each system is customized to your preferred fuel type and regional energy availability.

Our advanced recuperators capture waste heat from exhaust gases and preheat incoming combustion air, reducing fuel consumption while minimising oxidation and scale losses. This delivers significant fuel savings and increased heating capacity.

Trymax furnaces feature PLC-based multi-zone temperature control with real-time monitoring. Advanced models include IoT sensors and remote diagnostics maintaining ±25°C uniformity across billet sections.

Yes. Trymax offers customizable furnaces ranging from 1–120 TPH across multiple configurations (pusher-type, walking beam, top-bottom fired) adapted to your specific billet dimensions and production requirements.

Installation and commissioning take just a few days. Our team handles furnace setup, electrical and fuel connections, system testing, and comprehensive operator training with minimal production downtime.

Trymax provides automated diagnostics, remote monitoring systems, 24-hour online support, fast spare parts supply, and local service partners. Our IoT-enabled furnaces allow remote performance tracking and troubleshooting.

Yes. Trymax’s billet reheating furnaces supports all three fuel types with optimised burner systems. Dual-fuel and triple-fuel configurations allow switching between sources based on availability and cost.

Trymax’s billet reheating furnaces minimise deformation and scale through even heat distribution, optimised residence time, reduced oxygen levels, strategically positioned multi-burners, and precision support systems that protect billet integrity throughout the heating cycle.

Trymax conducts facility analysis covering your production flow, material specs, capacity needs, and existing infrastructure. We deliver custom solutions for capacity, fuel configuration, automation, space adaptation, and Iraq-specific operational requirements.

Trymax provides 5-year spare parts availability, 24-hour online support, fast parts dispatch, preventive maintenance programs, local service partners, and modernisation services ensuring long-term furnace reliability.