Get In Touch

- 55 Main Street, 2nd Block, USA

- [email protected]

- +000 (123) 456 88

Gallery

Get In Touch

- 55 Main Street, 2nd Block, USA

- [email protected]

- +000 (123) 456 88

Gallery

Heat Treatment and Industrial Furnaces in India by Trymaxfurnace

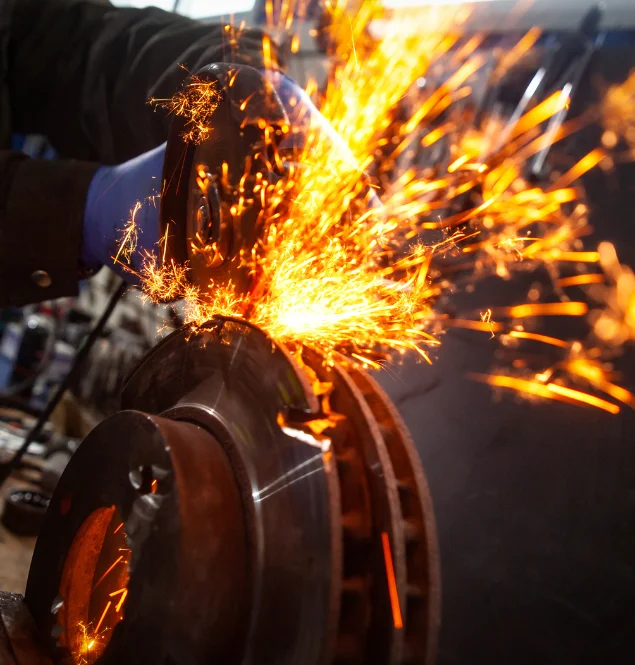

Heat treatment is the process of heating and cooling metals or glass to alter properties such as hardness, strength, and ductility. Common heat treatment processes include quenching, annealing, and tempering, each applied through controlled heating and cooling cycles. At Trymaxfurnace, we design and manufacture advanced heat treat furnaces, industrial furnaces, reheating furnaces, and vacuum heat treatment furnaces for diverse applications.

As trusted furnace manufacturers in India, we provide high-performance heat treatment furnaces tailored for steel, rolling mills, and industrial needs, ensuring superior durability and efficiency.

//Heat Treatment Furnaces Manufacturing

Heat Treatment Processes with Trymaxfurnace

Heat treatment is a controlled industrial procedure that changes the physical and mechanical qualities of materials to make them stronger, more durable, and better at doing their jobs. At Trymaxfurnace, a trusted furnace manufacturer in India, we specialize in advanced heat treat furnaces, vacuum heat treatment furnaces, and industrial furnaces designed for diverse applications. Our heat treatment furnaces support processes like annealing, quenching, tempering, and case hardening. As leading manufacturers of furnaces, we provide reliable heating treatment furnaces, reheating furnaces, and solutions for rolling mill manufacturers across industries.

What Is Heat Treatment?

Heat treatment is a controlled process of heating and cooling metals to enhance strength, durability, and performance. At Trymaxfurnace, a leading furnace manufacturer in India, we design advanced heat treat furnaces and industrial furnaces for precise heat treatment processes. Our heating treatment furnaces deliver efficiency, reliability, and consistency, ensuring metals achieve superior physical and chemical properties.

Heat Treatment Benefits with Advanced Furnaces ( Engineered for Precision, Built for Efficiency )

Heat treatment is an important step that changes how hard, strong, and conductive metals are. At Trymaxfurnace, a trusted furnace manufacturer in India, we provide advanced heat treat furnaces, industrial furnaces, and heating treatment furnaces designed for precision. Our heat treatment processes ensure durability, stress relief, and performance for industries needing reliable heat treatment furnaces.

Heat Treatment Furnaces in India ( Smart Systems for Safe and Efficient Operation )

Heat treatment is a process used to enhance metal properties like strength, hardness, ductility, and conductivity. At Trymaxfurnace, we provide advanced heat treat furnaces in India, designed for precise performance. Our solutions help industries achieve stress relief, durability, and chemical stability in metals, ensuring components meet demanding applications such as aerospace, automotive, and heavy engineering.

Heat Treatment Process Explained ( Smart Systems for Safe and Efficient Operation )

Controlled heating and cooling of metals to make them stronger, last longer, and work better is called heat treatment. The process modifies the metal’s microstructure, improving properties like hardness, toughness, and corrosion resistance. At Trymaxfurnace, India’s trusted provider of heat treat furnaces, we deliver advanced furnace solutions designed to achieve precise treatment results across various metals and applications.

Heat Treating Furnace manufacturers in India

Types of Heat Treatment Furnaces

By heating and cooling metals in a regulated way, heat treatment can modify their crystalline structure and make them operate better.This process enhances hardness, strength, ductility, and resistance to wear without changing the shape of the product. At Trymaxfurnace, we manufacture advanced heat treat furnaces in India designed for precision, efficiency, and long-term durability. Our furnaces support a wide range of applications, including annealing, hardening, quenching, and stress relieving, ensuring metals achieve the desired physical and mechanical properties. Annealing improves ductility and reduces stress, while hardening and quenching increase surface strength and stability.Stress relief makes things last longer by getting rid of any leftover stress. With digital controls, energy-efficient designs, and customizable configurations, Trymaxfurnace delivers reliable solutions for industries that demand superior quality heat treatment furnaces.

About Trymax Furnace – Trusted Industrial Furnace Manufacturers in India

Established in 2012 and headquartered in Mumbai, Trymax Furnaces Pvt. Ltd. is one of the leading furnace manufacturing companies in India. As experienced industrial furnace manufacturers in India, we deliver complete in-house capabilities—from design and engineering to fabrication, erection, and commissioning.

Over the past decade, Trymax Furnace has become a reliable industrial furnace supplier to various sectors, particularly the steel industry. Our product range includes:

- Billet reheating furnaces

- Aluminium billet heating furnaces

- Ladle and tundish preheaters

- AOD preheaters

- Soaking pits

- Industrial Burner

- Industrial Recuperator

- Heat treatment furnaces for Indian and global clients

Our focus on customization, energy efficiency, and quality engineering makes us a preferred choice among the best steel manufacturers, top rolling mills, and forging operations in India.

Established

Completed

Served

What Is Heat Treatment & Why Trymaxfurnace Leads the Way

Annealing, tempering, and quenching are all examples of controlled heating and cooling processes that improve a metal’s hardness, strength, and performance. At Trymaxfurnace, we deliver precision-engineered heat-treat furnaces across India, featuring robust construction, multi-zone PLC control, and highly accurate temperature profiling. Our systems ensure consistent uniformity, efficient energy use, and complete cycle automation with data logging. Trusted in forging, hardening, normalising, solution treatment, and PWHT applications, Trymaxfurnace supports industrial excellence with productivity, safety, and real-time control from loading to cool-down.

Trymaxfurnace’s Expert Heat Treatment Solutions

Heat treatment optimizes metal properties—such as strength, ductility, and wear resistance—via precise heating and cooling. Trymaxfurnace sells heat-treat furnaces all over India. They are built to last, with precise PLC-based multi-zone control, and automated heat-soak-cool profiles. Our systems deliver repeatable thermal uniformity and energy-efficient operation, backed by data-driven cycle management. From annealing and tempering to quenching and PWHT, Trymaxfurnace’s furnaces empower industrial processes with enhanced performance, dependability, and digital oversight for every treatment stage.

Heat Treatment Furnaces & Techniques by Trymaxfurnace

Heat Treatment Furnaces

Trymaxfurnace, is a trusted provider of advanced heat treatment furnaces in India, designed to improve the durability and performance of metals. Heat treatment is the industrial process of heating or cooling materials to achieve desired properties such as hardness, strength, or flexibility. Widely applied in metallurgy, manufacturing, and glass production, these furnaces ensure precise temperature control for consistent results.

Heat Treatment Techniques

Our furnaces can do a lot of different things, such annealing, tempering, quenching, precipitation strengthening, and case hardening.These processes alter metal microstructures, enhancing strength, toughness, and wear resistance.

Industries We Serve

How to Use an Industrial Furnace? ( Smart, Strong, and Fuel-Efficient )

Heat Treatment Furnaces Use by Trymaxfurnace

Heat treatment is a controlled process where metals are heated and cooled to alter their structure, improving strength, hardness, and durability. At Trymaxfurnace,we provide advanced heat treatment furnaces in India designed for precision, efficiency, and uniform heating. Our furnaces are widely used for annealing, tempering, hardening, and stress relieving in industries like automotive, aerospace, tool manufacturing, and heavy machinery. With reliable temperature control and energy-efficient designs, Trymaxfurnace ensures consistent results, helping industries achieve superior product quality and long-lasting performance through advanced industrial furnace technology.

Vacuum Heat Treatment ( // Reliable Heating for Consistent Steel Processing )

Trymaxfurnace provides advanced heat treat furnaces in India, enabling controlled heating under vacuum to modify materials’ structural properties, improving strength, durability, and performance

Soaking Pits Manufacturers in India

Vacuum Heat Treatment with Trymaxfurnace

What is Vacuum Heat Treatment?

Vacuum heat treatment is a new method that makes materials stronger and better by getting rid of impurities that occur when they come into contact with air, dust, and moisture.Over time, metals and alloys can react chemically, creating oxides, nitrides, or other unwanted compounds that weaken their properties. By heating materials inside a vacuum, these contaminants are removed either by vaporization or decomposition without the presence of oxygen. This helps to make sure that the structure is strong and the surface is clean and brilliant.Unlike traditional methods, vacuum treatment does not require costly gases like hydrogen or argon, making it safer, cost-effective, and more efficient.

Vacuum Furnaces and Trymaxfurnace Technology

At Trymaxfurnace, we provide advanced vacuum furnaces in India that deliver precision and reliability across industries such as aerospace, automotive, healthcare, and manufacturing. Our vacuum furnaces operate in a sealed chamber connected to a high-performance vacuum system that removes nitrogen and oxygen, preventing oxidation and contamination. Processes such as annealing, tempering, stress relieving, and hardening are carried out with exact heating, soaking, and cooling cycles to achieve superior results.

Our systems use Busch vacuum technology to combine backup pumps, boosters, and diffusion vacuum pumps to reach deep vacuum levels for steady performance. This ensures materials gain desired properties such as strength, durability, and a contamination-free finish—helping industries maintain high-quality standards.

Heat Treatment Furnaces in India by Trymaxfurnace - ( Engineered for Efficiency, Built to Perform )

Heat treatment is a controlled process of heating and cooling metals to modify their structure, improving hardness, strength, and durability. Industries like automotive, aerospace, and steel rely on these processes for precision and performance.

Why Choose Trymaxfurnace?

At Trymaxfurnace,we specialize in advanced heat treatment furnaces, including vacuum and industrial furnaces engineered for accuracy, energy efficiency, and long-term reliability. With PLC-based control, uniform heating, and customized solutions, we deliver consistent results for annealing, quenching, tempering, and stress relieving—empowering industries with superior quality and dependable furnace technology

Why Choose Soaking Pits?

Uniform Temperature Control

Fuel Efficiency

Proven Industrial Performance

Custom-Built Solutions

Automation & Safety Ready

What Our Clients Say About Our Services

Testimonials

Engineered for Efficiency, Built to Perform

Whether you need a custom-built solution for a compact plant or a high-capacity system for continuous production, our soaking pits are adaptable to your exact needs. With automation-ready controls, flexible fuel options, and rugged materials, they deliver consistent results shift after shift—ensuring long-term reliability and lower operational costs.

Read More

Our furnaces can heat billets with precision. The temperature can be managed manually by the operator or automatically using integrated control systems, ensuring uniformity in product quality. This precision makes Trymax Furnaces a preferred name among furnace manufacturing companies in India.

Trymax billet reheating furnaces offer flexible operational modes. You can run them continuously for high-volume applications or configure them for batch heating. Once the billet reaches the desired temperature, it is automatically ejected, thus streamlining your workflow and increasing productivity.

Our billet reheating furnaces are engineered to be highly energy-efficient and significantly reduce idle energy consumption. This helps lower operating costs and improves overall energy efficiency, making Trymax Furnaces a trusted industrial furnace supplier for energy-conscious industries.

By combining energy efficiency, safety, and high precision, Trymax billet reheating furnaces are the future of industrial heating in India and beyond. Trust one of the most dependable furnace manufacturing companies in India to deliver quality and performance you can count on.

Trymaxfurnace | Heat Treat & Industrial Furnace Manufacturer in India

Heat treatment processes like annealing, quenching, tempering, and stress relieving are essential for improving hardness, strength, and durability of metals. Trymaxfurnace, a leading furnace manufacturer in India, designs advanced heat treatment furnaces that deliver precise temperature control for reliable and efficient results across multiple industries.

Heat treatment furnaces are very important for changing the structure of metals so that they are more flexible, stronger, and more resistant to wear. At Trymaxfurnace, India’s trusted furnace manufacturer, our industrial heat treatment furnaces are engineered for accuracy and energy efficiency, ensuring consistent performance in automotive, aerospace, and steel industries.

As leading furnace manufacturers in India, Trymaxfurnace produces a wide range of heat treatment furnace types, including vacuum heat treatment furnaces, reheating furnaces, and industrial heat treatment furnaces. Each heating furnace is designed with PLC-based controls and energy-efficient systems to meet diverse industrial needs.

A vacuum furnace for heat treatment removes impurities such as oxides and nitrides, delivering cleaner surfaces and enhanced material durability. Trymaxfurnace manufactures advanced vacuum heat treatment furnaces in India, ensuring precision, deep vacuum levels, and consistent performance for aerospace, healthcare, and heavy engineering industries.

Trymaxfurnace stands out among furnace manufacturers in India for its expertise in designing industrial furnaces and heating treatment furnaces with multi-zone control, digital automation, and energy efficiency. Our furnaces are customized for annealing, hardening, quenching, and rolling mill manufacturing, delivering superior performance and long-term reliability.

Hardening, stress relief, and heat treatment are some of the things that an industrial furnace is used for. A reheating furnace, on the other hand, is used to heat steel slabs or billets so they can be rolled.Trymaxfurnace manufactures both types of furnaces in India, ensuring industries receive tailored heating solutions with consistent temperature control.

Trymaxfurnace’s heat treatment furnaces in India are built with smart PLC control, uniform heating zones, and energy-efficient designs. These heating treatment furnaces reduce cycle time, improve thermal uniformity, and minimize operational costs, helping industries achieve higher output with superior quality standards.

Trymaxfurnace supplies heat treat furnaces and industrial heat treatment furnaces to industries like automotive, aerospace, tool manufacturing, steel, and rolling mills. Our heat treatment furnace technology ensures metals achieve required hardness, toughness, and performance, supporting industries with dependable furnace systems across India.